Help Lightning Blog

Learn How To Reduce Truck Roll Costs In Field Service

Wondering how to reduce truck roll costs without hurting other important metrics, like customer satisfaction (CSAT) and customer retention scores? Well, fortunately, it is possible – but it takes a methodical approach. And that’s what we’ll be diving into today: the question of how you can quickly and effectively make some tweaks here and there to your day-to-day operations, and in the process, reduce truck roll costs while still spurring long-term growth for your business.

Let’s begin!

What counts as a truck roll?

Before we begin answering the question of how to reduce truck roll costs, we need to make sure we understand what exactly constitutes a truck roll. For the purposes of this article, when we use the term, we’ll be talking about the dispatch of a technician (via truck or any other vehicle), to address a customer issue, such as maintenance, installation, rearrangement, or a fix.

Industries such as oil and gas, telecommunications providers, and industrial equipment are all prime examples of businesses in which truck roll costs trend upwards and have the biggest potential to impact your bottom line.

Why reduce truck roll costs?

According to the Technology Service Industry Association, truck rolls cost the average business around $1,000 per dispatch. This number can easily increase or decrease depending on the availability of your staff (technicians working overtime will incur bigger costs). Also, you can ask about common dispatch times for the technician. This is because night calls and appointments made during rush hour may include their own extra costs. Finally, how long it will take to reach the customer in question.

What can you do to reduce truck roll costs, starting now?

1. Qualification, qualification, qualification

The saying “an ounce of prevention is worth a pound of cure,” has never been more true than when talking about truck roll costs. According to Aberdeen Group, 33% of truck dispatches will require a second trip, with 19% of that initial number a result of insufficient information on the original issue. Unfortunately, another 28% of these second dispatches are apparently due to wrong diagnoses the first time. So what do these findings tell us, exactly?

Well, ensuring that your customer service representatives gain the right information before any technician is dispatched is paramount. In fact, you might even find that when your associates do some extra digging, the issue can be resolved over the phone, or with the help of a technician via a video call.

This approach, of course, requires representatives to deep dive into customer issues from the outset. One way they can gain as much data as possible is to optimize communications with customers by seeing the issue for themselves first hand via AR-enabled technology, which we’ll investigate in step 2.

2. Technology is your best friend

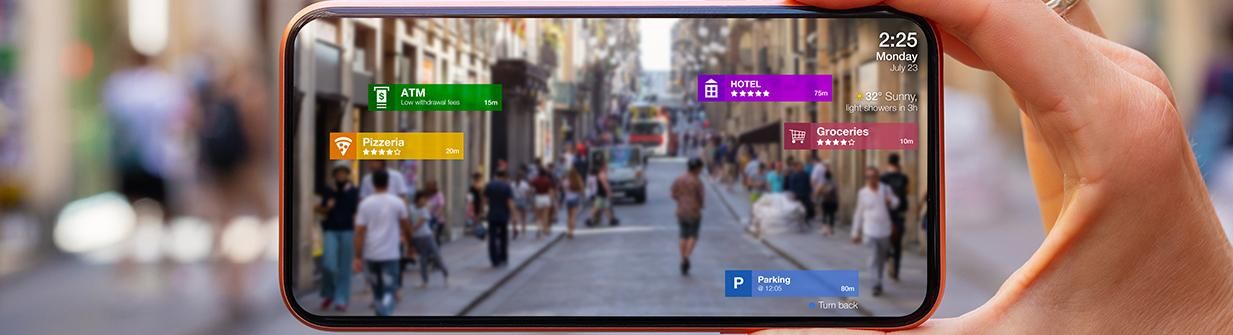

Given the importance of communication, clarity, and information when tackling a technical problem, you may want to empower your customer service team to reduce both first and second truck rolls through AR-enabled remote assist technology.

This means of communication essentially merges reality, and allows both customers and your staff to visualize issues, point out problem areas, and annotate and draw on the screen, so that if it is possible to solve the issue remotely – remote assist software provides you the best opportunity to do so.

And in the case that you require a technician? Representatives can take the recording and send these valuable insights to them ahead of time, helping them prepare if a truck roll is truly necessary. This results in increased access to information, and essentially means that technicians have a higher likelihood of solving the root cause of an issue the first time. In fact, it appears that – all in all – remote assist software reduces the number of second truck rolls by 35%.

(As an added bonus, the right remote first service technology is also likely to help you reduce AHT, increase CSAT scores, and enjoy a host of other advantages that benefit your bottom line).

3. Keep a categorized history

Chances are, truck rolls will be necessary at least some of the time. Luckily, though, you can keep track of these roll-outs, identify patterns and trends, and take actions to remedy repeat issues by keeping a categorized history of all roll-outs by customer, problem, resolution time, and so on.

At this stage, it’s also important to get feedback from technicians on their recent field experience. Do they keep getting dispatched to set up complex products or services? If so, could this step be foregone entirely by providing better instructions or dedicating a remote team, supported by remote assist software, to help struggling customers? Once you collect the right data and get feedback from representatives and other boots-on-the-ground workers, you can begin to proactively create alternative solutions to truck roll outs.

One additional way to reduce truck rolls and truck roll costs is providing self-service options for your customers. If you’d like to learn more about reducing truck rolls or providing customer self-service, get in touch for a free, no obligation demo.