Today’s companies are under tremendous pressure to provide superior service in addition to excellent products. When Diversey wanted to reduce truck rolls for its clientele, it turned to Help Lightning and merged reality technology.

What happens when something breaks in a place far from the people who know how to fix it? That is what is known as a truck roll. Sending someone or team out to diagnose and fix a problem in a van or truck is wasteful and inefficient. “Inefficient” and “wasteful” are two words Andrew Martin, a Global Portfolio Manager with Diversey, wants to avoid.

“Our customers buy our equipment because they expect it to work,” Martin said. “We give them operational readiness; when they hit the switch, it works and when it doesn’t, we get it repaired and troubleshot within a couple of minutes.”

When a tech does have to come on-site the company employs a system called ‘first-time right.’ This system ensures the tech knows the problem inside and out and has the right tools and parts for the job. Therefore both sides can manage their time effectively — that’s where Help Lightning has made all the difference. Learn more about truck roll costs.

Quick Solutions To Reduce Truck Rolls:

“There’s nothing worse than waiting for hours for service, or days if it’s the weekend,” Martin said. “Imagine having someone show up to diagnose a problem and having them say ‘Oh yeah, I can fix that, but I don’t have the part with me, so I’ll need to come back on Tuesday.’”

With Help Lightning’s merged reality software, techs get an over-the-shoulder view of the equipment that lets them diagnose exactly what’s wrong and how to fix the problem.

“It gives us a higher level of respect for what we can deliver,” Martin says, “Not just for our equipment but with the service itself. Our customers know they can count on us.”

Reduce Truck Rolls and Improve First-Time Fix Rates:

With Help Lightning, Diversey has increased its operational readiness and its ability to trouble shoot. In a system that’s still in the early stages, the company is currently looking to reduce truck rolls of at least 10-15%.

“We also estimate we’ve increased our first-time fix rates by 15-20%,” Martin said. “When you add that to the decrease in the truck rolls, that’s a great story.”

Resolution Times on the Rise:

The final proof of Help Lightning’s return on investment is a dramatic rise in resolution times. According to Martin, any time you can reduce the time between when something isn’t working to when it is up and running again—everybody wins.

“We track resolution times,” Martin said. “The time between when our customers call us with a piece of equipment that’s not doing what it’s supposed to do and when it’s fixed has been greatly reduced — probably by 20 to 30% — by using this system.”

How it Works:

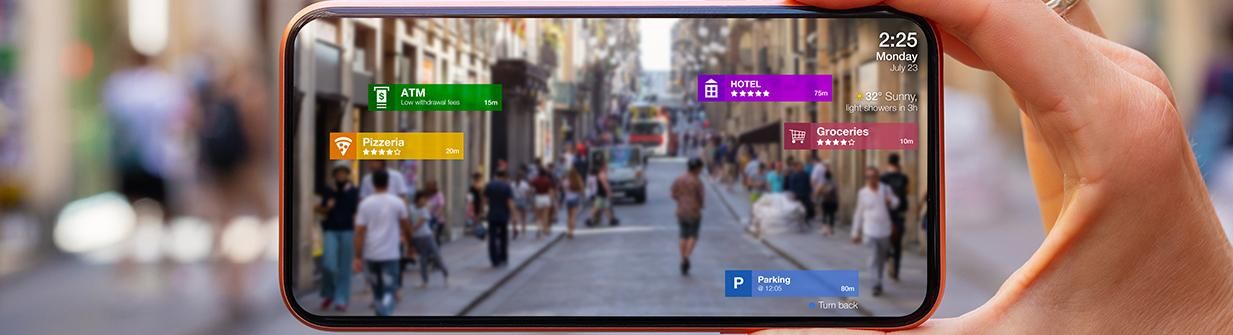

Help Lightning’s Merged Reality software works by blending two video streams into one collaborative work environment. That means the person in need of help can be watching a piece of equipment and see the expert’s hand reach in to toggle a switch or a screwdriver turning a screw. They can see written instructions appear on their device or watch as an arrow points to the exact wire that needs to be adjusted.

“It’s really just ease of use,” Martin said. “There’s no learning curve. It’s just like someone is right there with them and they get it.”

Want to see Help Lightning in action? Schedule a free demonstration our innovative merged reality solution.