Help Lightning Blog

Industrial Equipment KPI: 5 Positive Outcomes of AR-Enabled Remote Assistance Software

An industrial equipment KPI can be a tricky thing to improve upon but with an assist from AR enabled you can achieve positive outcomes. Unlike providers of SaaS software, tech companies, and other cloud-based businesses that face initial high upfront costs and only later enjoy almost painless scalability (thanks to their reliance on a largely subscription-based model), industrial equipment leaders can find it difficult to better key measures of success without compromising on quality of service. Indeed, padding one’s bottom line with measures such as increased CSAT scores, reduced handling times, and lowered truck roll costs, while still balancing overhead costs can be a difficult see-saw on which to balance.

So exactly how can you accomplish both those tasks? Well, in order to figure out how to see improvements to industrial equipment KPIs, like first call resolutions and custom retention rates, without that associated exponential increase in costs, we turn to the phenomena of remote assist software, and exactly what it can offer the industrial equipment industry.

What is remote assist software? And can it really help achieve an industrial equipment KPI enabled by AR?

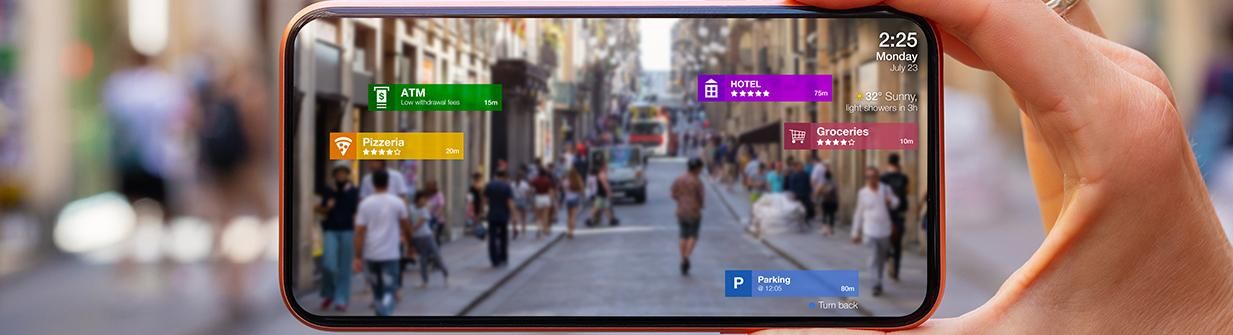

Remote support software, otherwise known as remote-first service, entails leveraging augmented-reality enabled technology to more easily accomplish a set task or series of tasks in a shorter period of time.

So how could this new technology slot into your industrial equipment company? Well, all those tasks that used to require a person (or in some cases, a whole team) to investigate, along with an expert when things would inevitably go sideways, now mean you don’t need to rely on in-person fixes. Your business no longer has to coordinate and wait for various truck dispatches. And your customers won’t have to wait as long for technicians as your employees commute from site to site.

In a nutshell, remote assist software means routine (and unexpected) tasks are: completed on time, more efficiently, and with more immediate results. But let’s hash out exactly what that looks like across the following industrial equipment KPIs.

Top 5 Industrial Equipment KPI Targets To See Improvements On When Enabled By AR:

1. First Time Fix Rates

You probably already know that machine downtime rate is any length of time that equipment is not available for production – whether that’s planned or unplanned.

But did you know that downtime is considered the largest source of lost production time for manufacturing? And that’s why getting your customers back up and running again is the best way to retain their business. In addition to increasing your existing contract sizes. One method to make up for this inevitable lost production time is to improve your first time fix rates.

First time fix rates, also known as FTFR, are one of the most important – and most frequently tracked – KPIs within the service industry. And for good reason: they can mean the difference between majority market share and struggling customer retention rates. In fact, because of their power to directly impact clients’ bottom lines, first time fix rates are one of the most (if not the most) critical factors in reducing customer churn.

So how can remote assist software lower your churn rate, and increase your retention rate? Well, remote assist software leverages merged reality, interactive screens, nonverbal communication, and optimized lines of communication. Doing so allow specialists access to the room in which a problem has occurred, alongside a boots-on-the-ground worker (or customer), and empowers them to solve the issue from where they sit – whether that’s a state of a whole country away.

The result? An average 20% improvement to first time fix rates (which also means reduced need for second trips).

2. Net Promoter Scores

Increase your CSAT score, and increase your annualized revenue.

By this point, we all know that word of mouth referrals are one of the most powerful means of supporting a company’s business development. And the industrial equipment industry is no different. In fact, 92% of people trust ‘word of mouth marketing’ (ie, individual referrals) over any other type of advertising. And clearly, the stakes are much higher, say, for an industrial plant than an individual consumer choosing a telecommunications provider. Each minute that a mechanical device or a machine is down, your customer is losing money. This includes examples like a a forklift, a production line, a cement mixer, or an industrial dryer.

By virtue of remote assist software improving first time fix rates by ⅕, this means your customer base has increased peace of mind that when they call your business, they’re more likely to see a satisfactory resolution the first time round. As such, they’ll be more likely to recommend your services to others.

3. Labor-Productivity Ratio

Labor as a percentage of cost is a critical industrial equipment KPI that can be supported by AR. It’s one that any employer would love to optimize for.

After all, if you can get better results out of the same employee – that means your labor productivity ratio just went up. And if you can accomplish this across the board, that means better ROI for the exact same spend, as well as a reduced need to hire more workers. So how do you increase your return on labor spend?

Simply put: you reduce (or eliminate) non-productive time. This means time that technicians and specialists waste traveling to and from customer calls. This is in addition to tens of minutes each day getting caught up on problems that could have been rehashed (and potentially even resolved) more easily and more succinctly over AR-software. As well as time spent sourcing supplies and tools that they could have been brought to the job site the first time around. Especially if communication been stronger and more streamlined from the start.

By introducing remote assist software, you allow technicians and specialists to walk into a customer’s facility or factory with zero commute time, and zero back and forth. They just click a button, and they’re virtually on site – immediately.

4. Mean Time to Repair/Service/Install

An often-overlooked industrial equipment KPI happens to be machine downtime rate’s not-so-distant cousin: capacity utilization. This refers to the rate at which potential output levels are being met or used. In this sense, not all pain points your customers experience have to do with unplanned maintenance. Sometimes, planned repairs or scheduled services can be just as cumbersome. This is because they also eat into this KPI that customers are trying to optimize for.

So what can you do, exactly? Afterall, safety checks are a necessary (and important) part and parcel of the manufacturing process.

Well, as you can imagine, making these necessary repairs, installations, and other interactions as quick and efficient as possible is beneficial for both your industrial equipment business, as well as your customer.

In the case of Help Lightning’s AR-enabled remote assist software, for instance, industrial equipment leaders who are users see a 30% improvement on resolution rate, on average. This means safety audits, annual check ups, and other necessary installations just got a whole lot quicker. This means your team’s time is freed up to work on other projects in this hereto occupied time.

(Interested in learning more about virtualized safety audits? Check out our article on how remote assist software makes this way easier for your team!)

5. Contract Attach Rates

Last but not least, we have contract attach rates. In this case, they refer to the increased percentage of new service contracts arising from existing customers who receive top notch service.

Indeed, when your customers experience positive changes, such as reduced plant downtime, expedited planned maintenance, and improved first time fix rates, it only follows that they will want to outsource more tools and equipment to the industrial equipment provider that’s offering the best value and the best return on investment.

Interested in learning more about the positive outcomes remote support software can offer your industrial equipment KPI goals when enabled by AR?

Get the smart KPI tracking guide here, or review our articles on how remote assist software improves first time fix rates, as well your team’s productivity levels! Alternatively, get in touch to schedule a free, no-obligation demo. You’ll learn about how Help Lightning’s remote first service technology can drive results for your business.